Connected Systems Intelligence Closing Insights-To-Action Gap

Factory of the Future

With the advancement of artificial intelligence (AI) and cognitive manufacturing, Industry 4.0 is creating a whole new realm of possibilities for improving manufacturing, from suppliers, across the factory floor, and through to customer units in the field with actions taken upon intelligence.

ICURO has been deploying intelligent systems, which is a step towards the factory of the future. The smart factories are equipped with cyber physical systems which include advanced sensors, embedded software, and robotics that collect and analyze data and allow for better decision making in tandem with information technology systems such as ERP, supply chain, CRM. Manufacturers are realizing benefits in sustainability, productivity improvement, operational efficiency, and equipment uptime.

Composite AI Platform For Industry 4.0

Industry 4.0 platform provides ease of access for the manufacturers to big data collected from sensors on the factory floor thereby providing real-time visibility of manufacturing assets and provide tools for process simplification and efficiency improvements across the value chain. The composite AI platform developed by ICURO connects a wide range of systems from Industrial IoT, cloud, and AI driven through visual and acoustic insights, digital twin, edge computing, and cyber security. We deliver an enterprise AI roadmap to manufacturers in three steps. Step one begins with strategic goals and opportunity discovery process where AI can enhance, automate, and accelerate. Step two lays out the foundation to define intelligent workflows for key business actions and realization of benefits. Step three brings you closer to a constantly learning enterprise that adapts to business changes and delivers strategic growth outcomes.

Tapping Mission Critical Data

Manufacturers generate billions of data every day from shop floor to usage. At the shop floor in a manufacturing plant data from conveyor belts, assembly lines to final testing involves robots, machine condition monitoring systems, assembly units, and more. Each of these units generate large volumes of data continuously which are monitored by factory subsystems. ICURO platform identifies the critical data from big data sources for generating and validating operational and strategic actions real-time.

- Prebuilt machine learning models for production line streaming critical data

- Edge-centric machine learning models for early warning of system availability

- Data driven analytics systems for sustainability and energy optimization

- Data driven decision metrics for consumption to plant stakeholders

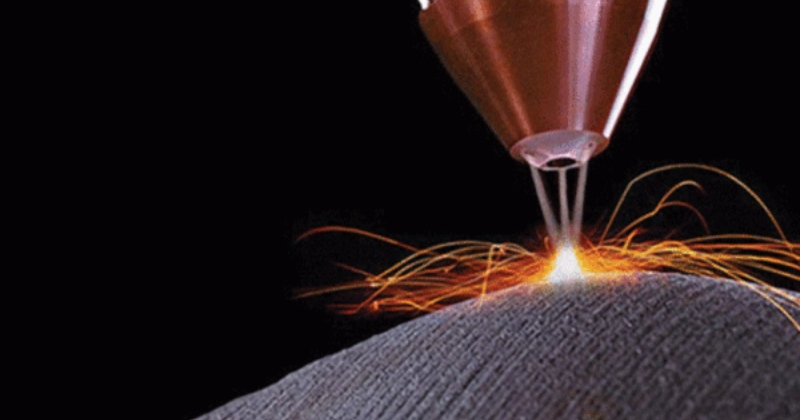

Active Inline Quality System

Shop floor quality engineers, site engineers, production managers are faced with mundane quality control systems throughout the supply chain. ICURO has implemented artificial intelligence (AI) vision systems to manage quality proactively by embedding an active inline quality system in the manufacturing process. This is an active feedback system to detect and correct at the point of action at every stage of production lifecycle and it consists of following features.

- Production line specific visual analysis providing active diagnostic recommendations and implement corrective actions

- Integration with existing sensors and robots enabling real-time analysis for correlation and anomalies

- Image analytics coupled with ground truth validation that aids in continuous learning for correct decision making

- Automating and scaling from visual inspection to asset management

- Detection and correction at the point of installation

Knowledge-driven Guidance

Equipment optimal usage is a key factor for managing the operational cost and assisting shop floor mechanics in efficient operations. ICURO machine learning models for preventive maintenance, predictive maintenance, knowledge management, remaining useful life analysis, warranty management systems have assisted manufacturers to increase uptime and availability of equipment significantly.

- KPIs to address greater asset visibility, reduced maintenance costs, worker health and safety, and site safety improvements

- Knowledge graph based on user manuals for rapid knowledge of machine behavior

- Prebuilt machine learning models to ingest data sources based on input, control, influencing parameters

- Predictive algorithms for critical equipment failure avoidance and advise the user on how to increase up-time and availability

Advanced Production Performance

Manufacturers are utilizing the advanced analytics capabilities with new sources of real-time data to gain predictions and prescription on improving equipment availability and performance. Using prebuilt industry models, manufacturer can optimize process parameter settings and product quality, stabilization of processes, inspection plans dynamization, and formulation of model-based inspection processes.

- Augmenting production through accelerators for mechatronics driven advanced manufacturing systems

- Accelerators for adaptive smart manufacturing systems and automation.

- Prebuilt machine learning models on equipment optimization for effective usage

- Worker factory assistant for asset management and usage

Strategic Partners

Solution Partner of ThingWorx, a PTC business, the global leader with an unique portfolio of CAD, PLM, IoT, and AR technologies work together to create a powerful digital thread foundation that enables faster data continuity across your business for better collaboration between your teams. Companies from industries such as industrial equipment, high-tech, automotive, aerospace and defense, life sciences, and more use PTC’s best-in-class solutions to achieve their digital transformation goals and differentiate their business.

As a Solution Partner, ICURO has extended ThingWorx platform features with advanced machine learning techniques and robotics powering enterprise use cases in manufacturing industry ranging from global industrial equipment manufacturers to automotive companies.

Artificial Intelligence (AI) Premium Member of NVIDIA, the global pioneer in accelerated computing in artificial intelligence and computer graphics transforming industries valued at more than $100 trillion, from gaming to healthcare to transportation, and profoundly impacting society. Engages in the design and manufacture of Graphics Processing Unit (GPU) segment consisting of product brands, including Tesla and DGX for AI data scientists and big data researchers, and GRID for cloud-based visual computing users. The Tegra Processor segment integrates an entire computer onto a single chip and incorporates GPUs and multi-core CPUs to drive supercomputing for autonomous robots, drones, and cars.

As the AI Premium Member, ICURO has implemented Jetson series of AI system-on-chip, the world’s fastest edge computing processors ranging from TX2 to Xavier in delivering shop floor edge systems for AI vision-based inspection and mobile robots.

More in Manufacturing

Warranty Analytics

Warranty repairs are often viewed by manufacturing businesses as liability as they cost the manufacturer in cash to pay for warranty service and replacement parts. However, warranty repairs also provide information that a manufacturer can use to improve its understanding of its products, its finances, its suppliers and third-party OEMs, and its customers.[…]

Smart Maintenance and Operations

Production facility managers typically use corrective maintenance which is costly in terms of downtime, labor use, working capital, and unscheduled maintenance. The cost of machine downtime is high: according to the International Society of Automation, $640 billion is lost every year. Also, at a plant level a typical factory loses between 5% and 20% of its manufacturing capacity due to downtime.[…]

Waste Reduction

Global manufacturers are on a journey to transition from waste reduction to wealth creation. The global manufacturing industry is estimated to be worth $40 trillion. While its waste accounts for 20% which is significantly high, classical statistical methods and experience-based decision rules have failed in highlighting deficiencies in waste management.[…]

Implementation Roadmap

Building and delivering an enterprise AI roadmap can divided into a three-step process. Step one begins with strategic goals and opportunity discovery process where AI can enhance, automate, and accelerate. Step two lays out the foundation to define intelligent workflows for key business actions and value realization. Step three brings you closer to a constantly learning enterprise that adapts to business changes and delivers strategic growth outcomes.

Automate

- Value Engineering

- Hybrid Dataflows

- Scalable Operations

Predict

- Intelligent Workflows

- Business Decisions

- Scalable Outcomes

Prescribe

- Explainable AI

- Value Observability

- Business Adaptability