Global manufacturers are on a journey to transition from waste reduction to wealth creation. The global manufacturing industry is estimated to be worth $40 trillion. While its waste accounts for 20% i.e., $8 trillion. Classical statistical methods and experience-based decision rules, many times failed in highlighting deficiencies in waste management. Make to stock strategies have problems in product customization era with shorter product life. Also production is usually planned in excess and overproductions are very likely to occur leading to several additional costs like packaging, internal and external transportation, storage including adding waste to the supply chain.

In batch-based manufacturing, some batches will have destructions some don’t have and the quantity of destructions vary significantly. We also optimize the chemical dosage used in manufacturing industry to eliminate unnecessary waste treatment and reduce cost of disposal. We help monitor process efficiency across facilities for performance anomalies and explore predictive maintenance as a process for reducing emission water energy and material waste reduction. This also ensures to maintain equipment based on performance conditions, reducing downtime.

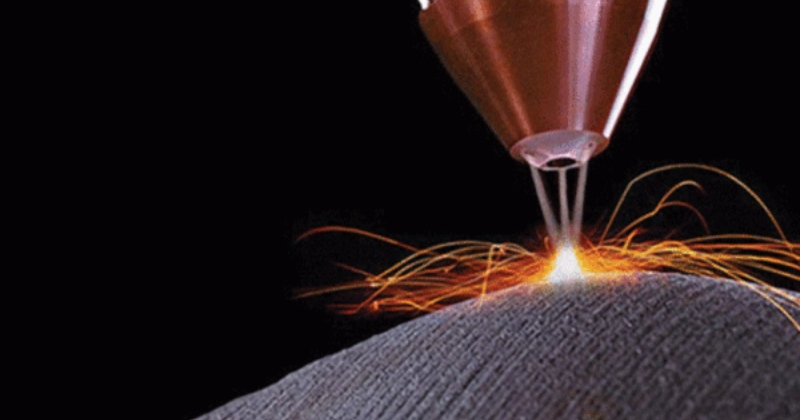

We formulate AI based design and control systems developed specifically for waste minimization using waste annotation techniques based on computer vision and it separate the waste in two parts; product which consists of raw materials, powder, liquids etc. and packing material. This is an important step in operationalizing lean manufacturing, we help the process engineers predict and prevent production waste by identifying areas of loss and prescribing focused actions that reduce product defects and production inefficiencies. waste is a strategic operational loss in manufacturing, but factories that harness industrial AI technologies as an integral part of their lean methodologies can continually improve their production processes to minimize waste.

Sustainability metrics enabled with predictive algorithms spot performance anomalies that increase the manufacturing waste before they occur. A step wise model selection algorithm based on the akaike information criterion. Bagging is a general clustering technique that can be applied to combine regression or classification models on features selected for identifying causative factors for waste creation. A large number of tree-based models are fitted to subsamples of the training data. Boosting applies a similar philosophy to the one used in bagging, where several weak predictors are combined. Recursive boosting applies the models, so that each model improves the predictions of waste from the previous ones.